World Tour was released on Amazon in digital & paperback.

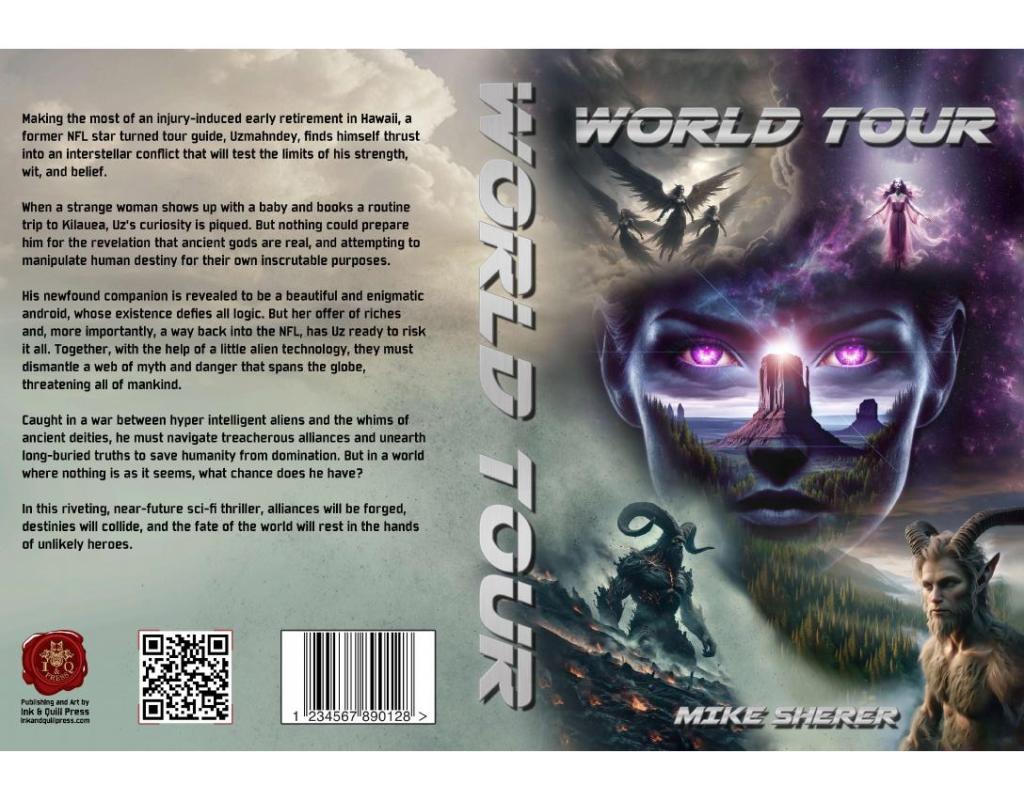

Ink & Quill sent me the final cover for World Tour.

Ink & Quill is solid on the April 10 release date.

Ink & Quill sent me the updated cover design and cover blurb for World Tour.

The cover blurb:

“Making the most of an injury-induced early retirement in Hawaii, a former NFL star turned tour guide, Uzmahndey, finds himself thrust into an interstellar conflict that will test the limits of his strength, wit, and belief.

When a strange woman shows up with a baby and books a routine trip to Kilauea, Uz’s curiosity is piqued. But nothing could prepare him for the revelation that ancient gods are real, and attempting to manipulate human destiny for their own inscrutable purposes.

His newfound companion is revealed to be a beautiful and enigmatic robot, whose existence defies all logic. But her offer of riches and, more importantly, a way back into the NFL, has Uz ready to risk it all. Together, with the help of a little alien technology, they must dismantle a web of myth and danger that spans the globe, threatening all of mankind.

Caught in a war between hyper intelligent aliens and the whims of ancient deities, he must navigate treacherous alliances and unearth long-buried truths to save humanity from domination. But in a world where nothing is as it seems, what chance does he have?

In this riveting, near-future sci-fi thriller, alliances will be forged, destinies will collide, and the fate of the world will rest in the hands of unlikely heroes.”

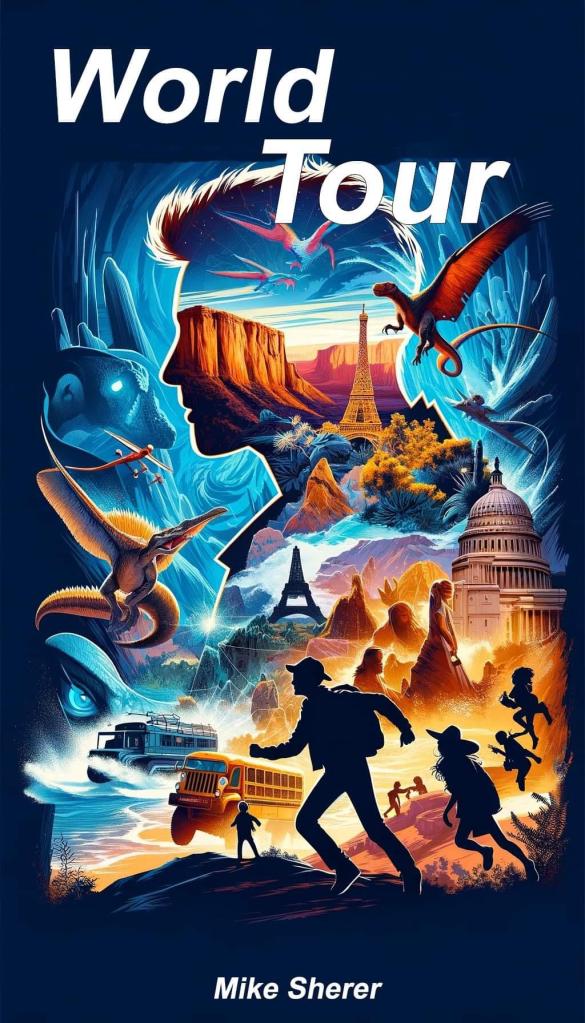

Ink & Quill sent me a new image for the book cover.

Ink & Quill just sent me an image they intend to use as the backdrop for the cover:

The first cover image Ink & Quill sent me:

On November 10, 2023, I signed a contract for publication of my science fiction novel World Tour with Ink & Quill Press.

Injured NFL player leads an invading alien force around the world to liberate humanity from parasites who have infected them since prehistory. An alien invasion just might save humanity. From the Earth.

First stop on the World Tour – Kilauea, Hawaii.

First review on my science fiction novel I am submitting for publication:

Your work was found to be a captivating, thought-provoking read offering a unique addition to the science fiction genre as a thrilling tantalizing read. Throughout there is a compelling honesty well-paced against the thrilling twists and turns; combining a deep emotional effect with an excitement that drags the reader to the edge of their seat beyond the final suspenseful scenes. Placing the problem in an inanimate, innocent object like Charlie’s dinosaur is the perfect contradictory action for the plot and is effective in showing the overlooked dangers in our world, or any world. Supported by detailed world building; a nuanced and complex cast, an immersive fast-paced ‘World Tour’ is undoubtedly a well-written and crafted novel worthy of attention. – Austin Macauley

Second stop – Sailing Stones, Death Valley NP, California. Heading east from Hawaii around the world.

Other stops on the world tour:

Mono Lake, California

Old Faithful, Wyoming

Spotted Lake, Canada

Devil’s Tower, Montana

Eternal Flame Falls, New York

Skaftafellsjokull Glacier, Iceland

Fingal’s Cave, Scotland

Giant’s Causeway, Ireland

Long and Black Lakes, Azores

Richat Structure, Mauritania

Eisriesenwelt Ice Cave, Austria

Babele, Romania

Pamukkale, Turkey

White Desert, Egypt

Well of Barhout, Yemen

Darvaza Gas Crater, Turkmenistan

Lake Kaindy, Kazakhstan

Lake Baikal, Russia

Stone Forest, China

Reed Flute Cave, China

Chocolate Hills, Phillipines

Lake Hillier, Australia

Tessellated Pavement, Australia

Moeraki, New Zealand

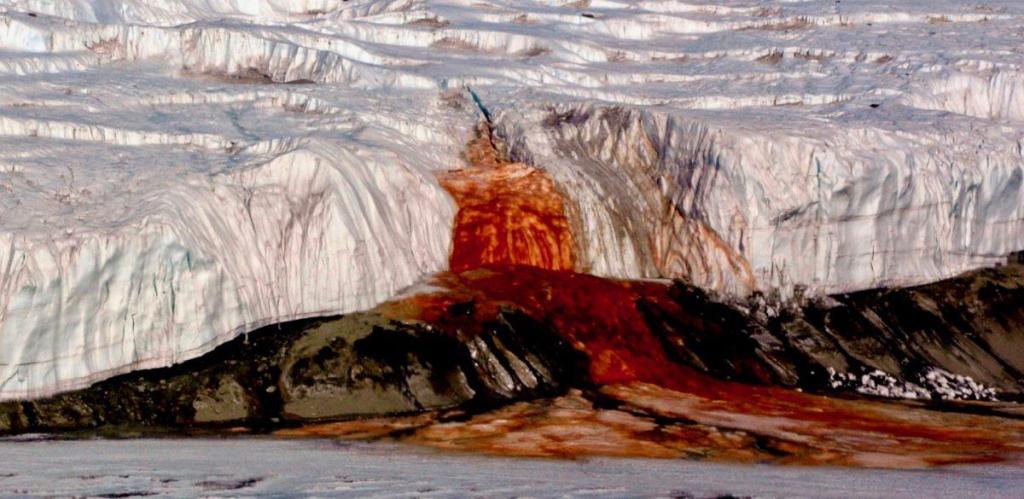

Blood Falls, Antarctica

Marble Caves, Chile

Salar de Uyuni, Bolivia

Cano Cristales, Columbia